-

- Types Of Milling Machine

- Universal Milling Machines

- Small Milling Machine Sale

- Small Cnc Mills

- Milling Machines Small

- Mini Milling Machine Cnc

- Mini Lathe Milling

- Milling Machine Vs Lathe

- Milling Machine Vs Drill Press

- Milling Machine Universal

- Milling Machine Rate

- Milling Machine Prices

- Milling Machine Manuals

- Milling Machine Horizontal

- Milling Machine For Sale

- Milling And Drilling Machine

- Manual Milling Machine

- Lathe Vs Milling Machine

- Knee Milling Machines

- Horizontal Milling Machines

- Gantry Milling Machines

- Gantry Cnc Mill

- For Sale Cnc Milling Machine

- Drilling Milling Machine

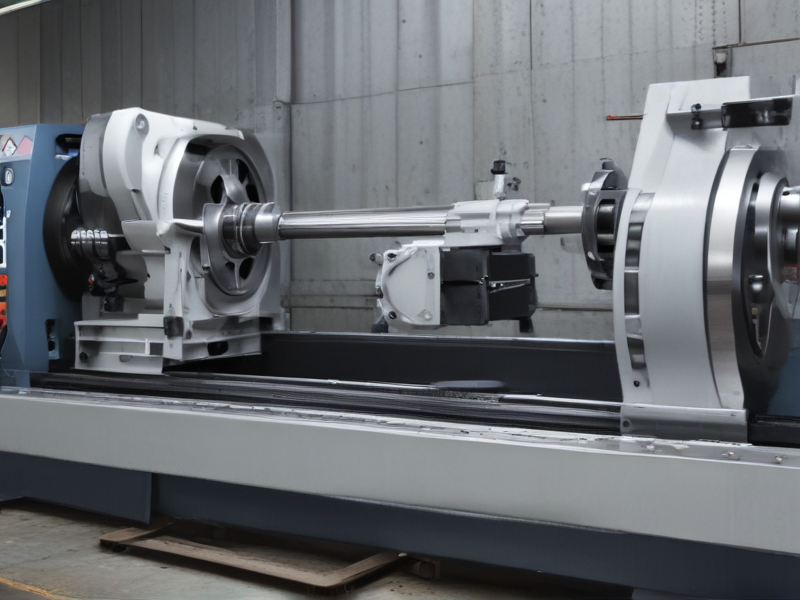

- Lathes Machine

- Steel Lathe Machine

- Vertical Lathes

- Rent A Lathe

- Parts Of Lathe

- Metal Lathe Components

- Machine Lathe

- Mini Lathe Milling

- Milling Machine Vs Lathe

- Meaning Of Lathe

- Manual Lathe Machine

- Lathe Working

- Lathe Vs Milling

- Lathe Small

- Lathe Pronunciation

- Lathe Part Diagram

- Lathe Machining

- Lathe Machine Rate

- Lathe Machine Operations

- Lathe In Spanish

- Lathe 5 Axis

- Large Lathe

- Heavy Duty Cnc Lathes

- Diagram Of Lathe Machine

- Components Of A Lathe

- Axis Cnc

- Surface Grinding Machine

- About

- Newsletter

- Whatsapp 8615951276160

- Types Of Milling Machine

- Universal Milling Machines

- Small Milling Machine Sale

- Small Cnc Mills

- Milling Machines Small

- Mini Milling Machine Cnc

- Mini Lathe Milling

- Milling Machine Vs Lathe

- Milling Machine Vs Drill Press

- Milling Machine Universal

- Milling Machine Rate

- Milling Machine Prices

- Milling Machine Manuals

- Milling Machine Horizontal

- Milling Machine For Sale

- Milling And Drilling Machine

- Manual Milling Machine

- Lathe Vs Milling Machine

- Knee Milling Machines

- Horizontal Milling Machines

- Gantry Milling Machines

- Gantry Cnc Mill

- For Sale Cnc Milling Machine

- Drilling Milling Machine

- Lathes Machine

- Steel Lathe Machine

- Vertical Lathes

- Rent A Lathe

- Parts Of Lathe

- Metal Lathe Components

- Machine Lathe

- Mini Lathe Milling

- Milling Machine Vs Lathe

- Meaning Of Lathe

- Manual Lathe Machine

- Lathe Working

- Lathe Vs Milling

- Lathe Small

- Lathe Pronunciation

- Lathe Part Diagram

- Lathe Machining

- Lathe Machine Rate

- Lathe Machine Operations

- Lathe In Spanish

- Lathe 5 Axis

- Large Lathe

- Heavy Duty Cnc Lathes

- Diagram Of Lathe Machine

- Components Of A Lathe

- Axis Cnc

- Surface Grinding Machine

- About